Federal Pacific Electric Circuit Breaker Demystified!

By David Harsche, CMECP™

Federal Pacific Electric Circuit Breaker Demystified!

FPE used dissimilar metals which creates corrosion, impedance, and excessive heat that lead to failure.

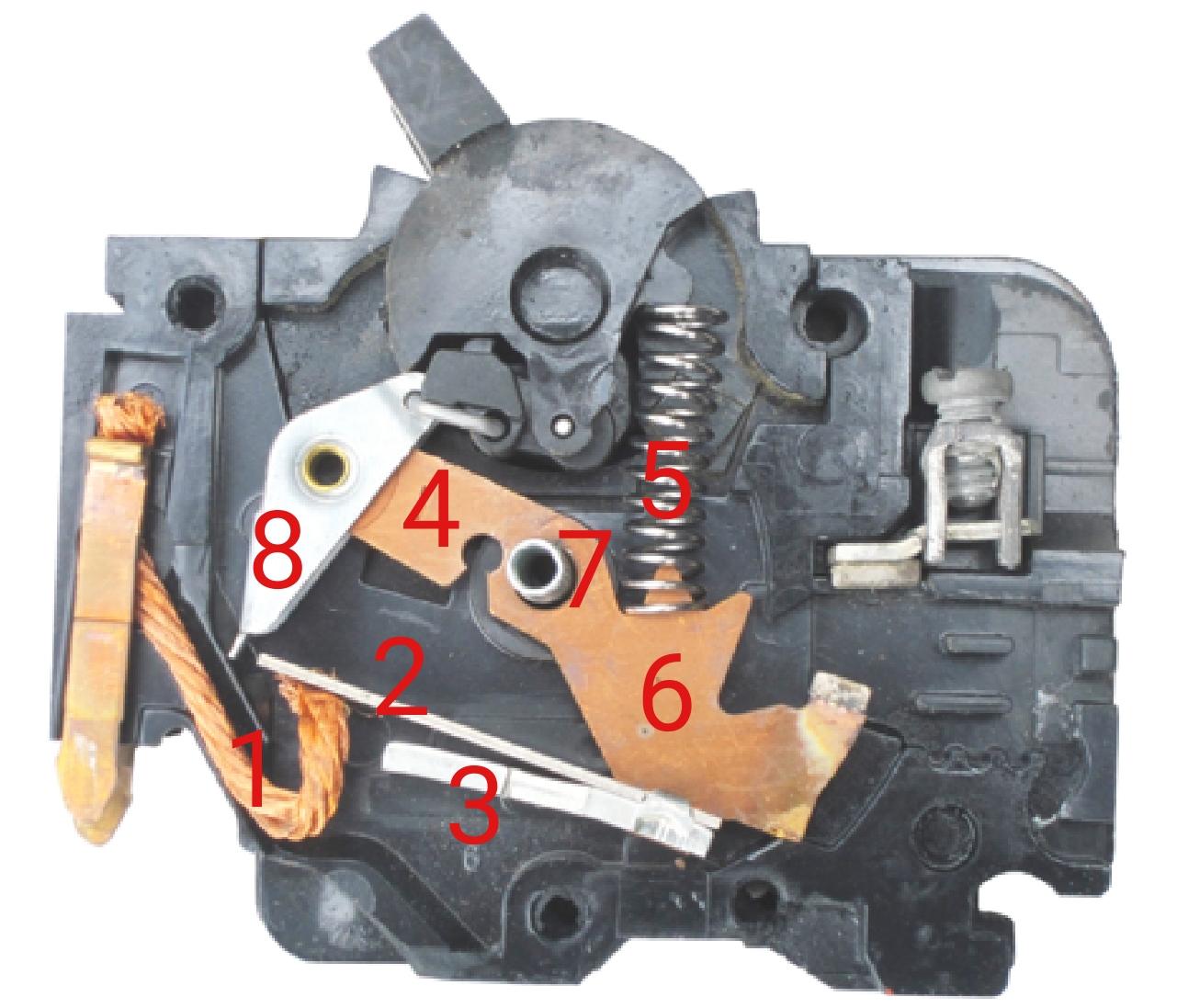

(1) Improper routing of the conductor could prevent the wire to contract under a fault which can cause the breaker not to Open. In other breakers the conductor was in contact the electromagnet block which can impede its function. The main spring in some cases was stretched abnormally and could bind.

(2) A electromagnetic block made of ferrous metal and the

(3) Bimetal element parallel to it. High currents create a magnetic field on the electromagnetic block which creates a pulling force on the Bimetal element, (

4) releasing the trip arm.

(5) The spring is the source of the energy that will compress and open the breaker mechanism.

(6) The copper armature must rotate on (7) A shaft made of a steel coil spring which increases friction and brings dissimilar metals in contact. Wires and rivets that act as shafts are in contact with dissimilar metals.

(8) The trip lever is activated by a U shaped conductor has one end in a plastic cam and the other end in the steel trip lever. The mechanical function of the breaker is only as good as the weakest link and FPE had many.

The picture shows the referenced numbers.